Ansible provisioning

I don’t have the energy to turn this into a proper Ansible tutorial that’s generic enough to be safely shared so I’ll be brief here.

Basically, when I set up the firmware image, I gave it my username and ssh key so that I’d be able to just run Ansible.

And then I’ve got a set of standard roles already set up that do things like give me a proper home directory with the right files, docker, etc.

Part of the nice thing about a tool such as Ansible there’s a community role that wraps up very nicely the care-and-feeding for getting Docker going. And if something zaps the file structure of my Pi’s SDcard, I can just start fresh and everything will be back where I set it up, more or less.

In order for this to work, when I’m tweaking the configs, I need to make the changes via Ansible and apply them instead of making the changes locally.

Klipper firmware build

prind is fairly close to what I want and is going to save me a lot of effort.

Except I don’t really need the Docker Compose part. And, actually, the idea of aliasing make weirds me out in general.

So here’s my shell script, which mirrors what the prind docker compose file is doing:

#!/bin/bash

VERSION=v0.12.0-143-g01c7befa

docker run --entrypoint make --rm \

-w /opt/klipper \

-v ./config/build.config:/opt/klipper/.config \

-v ./out:/opt/klipper/out \

-it mkuf/klipper:$VERSION-tools $@And the process to build an image looks like this:

mkdir config

touch config/build.config # to force the creation of a file to map instead of a directory

./build-image.sh menuconfig # replace make with the name of the script

./build-image.sh I kinda left this ugly and just manually moved the built klipper binary over to copy it.

Electronics and wiring

- Ended up putting on a new JST-XH connector on the bed thermistor wires I’d cut on Step 8.

Skirts & Panels

- The way the order of setup is going, it is way too easy to end up dropping a screw into the power supply while putting the skirts on. I’d go so far as to call this a design flaw in ways that all of the other side-effects of a smol babby printer are not because this is something that could start a fire.

- The straing relief and umbillical support is just a smidgen too small.

- I think the most annoyingly badly documented part so far is the umbillical. It’s 100% guesswork, which is fine for me but might present a lot of problems for a new user.

My BTT SKR Pico sucks

I was just checking through all of the wiring because it’s actually at a point where I could power it up and start getting it printing PETG without the full chassis on. So I went through and checked all of the wires to see if everything seemed secure.

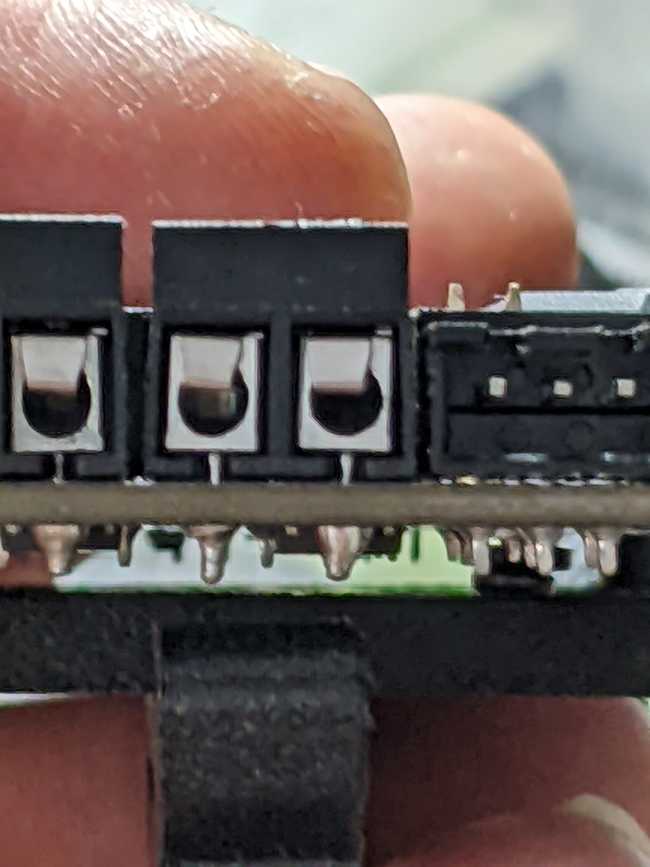

One of the screw terminals is bad. The one for the hotend, ironically, which is also the one that went bad on my Ender 3v2.

The screw terminals are the sort where there’s not a good-side/bad-side thing, you can just jam in a wire and it’ll end up on the right side. You can see how the other ones have a metal contact that bends down to hold the wire in place and make the circuit. And the one on the farthest right… no matter what I do with the screwdriver, the contact never moves.

The thing that concerns me about my particular Pico is that all of the screw terminals feel flimsy as I tighten them where the Creality board for my Ender 3v2 also has cost-optimized screw terminals but those aren’t nearly as bad. These are, and understand that I default to using screw terminals for my electronics designs, probably the worst screw terminals I’ve ever seen.

Also, as I said last time, the heat sink is held on by what feels like putty.

The LDO kit… which is what folks tell you to get because you’ll end up swapping out all of the parts from your non-LDO kit till you get to the LDO version… has a SKR Pico. So I’d like to think that if all of the SKR Pico boards were this bad, there’d be a lot more unhappy people.

Other than sending in a support ticket, do I?

- Buy another SKR Pico so I’m not sitting around staring at a broken printer for however long formbot and/or BTT take to figure things out because it can’t hurt to have a spare, hoping that I’ll get lucky on a $39 control board?

- Buy a different board that’s fairly compact because maybe BTT is making the SKR Pico too cheap. Say the SKRat control board?

- Get out the soldering iron and fix it myself because I can and because there isn’t a better replacement anyway? Maybe put a Phoenix-style connector this time?