This work session aligned to the 8th anniversary of Voron’s release

PSU mounting

I’ve found a few options for mounting the PSU not using VHB tape:

- Using screws through the deck plate which is kinda fine, but my goal here is to be able to swap it out over time

- A DIN Rail mount that doesn’t modify the printer where the DIN rail is mostly used as a structural member moreso than anything else, which also requires you to cut a DIN rail to a specific length.

- The proper DIN rail mounting system that uses the taller skirt and requires the bigger skirts mod.

- The PSU mod that may or may not work with the existing skirt but slides in there underneath

- The rail-less screw version that is kind of a big print that requires supports.

I think I’m going to try the last option. I printed it with PET-GF and test-fit it, which revealed that I had two nuts in the wrong place, so I had to the screws on the Z-axis to get them in the correct place. Thankfully I’d stopped just short of getting the Z-axis aligned, so I wasn’t taking it too far out of whack.

No-Drop nuts and the edge cases

It’s an understandable problem… but there’s a lot of context required in the Voron community because everybody’s building out their printer, applying customizations, and not everybody’s a documentation writer and it’s a lot easier to distribute STL files and a lot harder to distribute valuable context.

Part of my goal of writing up my build log is to write at at least some of the context, as it is when I built the printer.

Ergo, the story so far on No-Drop nuts:

You probably want to print the No Drop Nuts from the f-zero repo that never made it up into the users repo because they seem to be a lot less fiddly, assuming that you can get them to stick to the build plate. I like PET or PET-GF because it’s extra-sticky!

So far, the cases where No-Drop nuts will interfere:

- Four nuts on the front door.

- One nut on the back skirt where the power socket screws in.

The second one is a bit of a problem, but since I’m probably going to redo the skirt regardless I’ll leave one screw out. The first one I am catching in time to replace it.

There’s a set of 10mm NoDrop nuts that should be good for the front door. What I did instead, and in a few other cases, was sandwich an extra bare nut between two NoDrop nuts.

Camlocks needed to be carefully un-wedged

I did an assembly error because the manual doesn’t quite cover what direction the camlocks in the idler mount are supposed to go, so one of them was backwards and that was a bit tricky to convince it to come out.

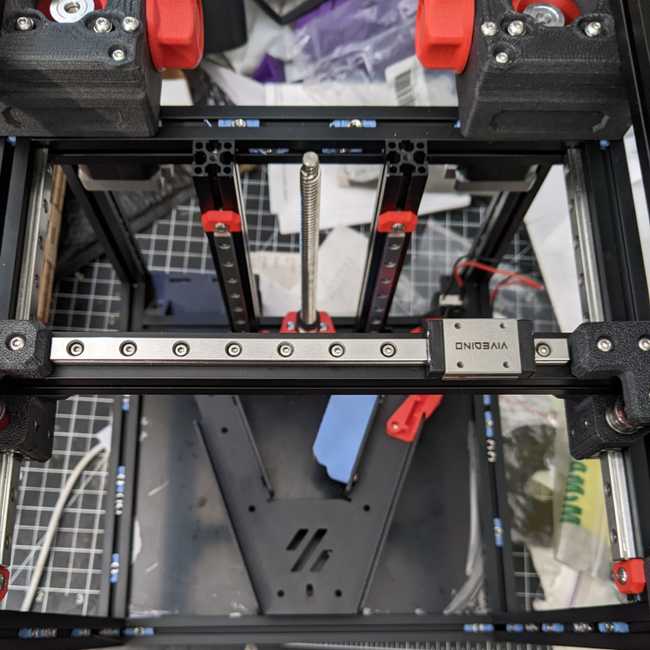

X Axis

- I’ve had a few cases where, because of the angle chosen in the manual, I spent a bunch of time digging through the 3D printed parts box trying to find something, only to realize that it was there the whole time. The XY joints are some of those parts. In a few cases, it would help to show the opposite side of the part, I think. Then again, I am running out of 3D printed parts in the box!

- The M2x10 self-tapping screws are annoying. I finally found one bit in one driver set that seems happy driving them? It’s a PH-0 from a frighteningly cheap Harbor Freight set.

- Instead of pre-loading a nut and then screwing the bolt in, I instead decided to just insert the two brackets with the screws and nuts already inserted, which means that I don’t need to think about the No Drop nuts and it also makes the whole thing less annoying.

Summary

I ran out of weekend before I worked up the energy to actually cut the belts, LOL. It’s a very imposing thing!