Mystic was visiting a while ago and we were doing the “parallel play” thing where we were both working on different stuff the same time. And then she realized that she needed some springs, so we walked to the local Ace Hardware, which I’d never actually been in, so we had to also browse the place.

I put one foot in the glue aisle and she looks at me and says “We are no longer friends”

(She’s kidding of course. She just really hates most adhesive products because a glued thing came apart during judging and so she’s gotten really good at designing things that can be bolted or screwed or snapped or whatevered together such that you can maintain them later, which is great because we’re also both extremely mad at this person who blandly suggests that it’s OK to hot-glue a Li-Ion battery down in a cosplay)

Anyway, the thing that finally came to fruition was my particular answer to the “How do I assemble my Zero without all that VHB tape” problem.

Print head

- The instructions aren’t clear so I’m doing things the way I did the Mosquito I put on my Ender 3v2: Apply a liiiiitle tiny bit of Boron Nitride thermal paste to the thermistor and heating cartridge, shove them in, either let them dry overnight or warm them up at 90°C for ten minutes. I ended up deciding it was easier to wire up if I put the wires for the heater sticking out the opposite side as the thermistor and dumb-lucked the sides.

- I do not see any instructions for what kind of screw to use for the umbillical PCB. I ended up using a M3x8 thread-forming screw. The folks on the Voron discord suggested that it was probably OK to just use a M3x6 screw and thread it in to the plastic.

Electronics and wiring

- Okay here’s where I slipstream the Voron V0.2 Electronics DIN Rail Bracket into my build. I had printed some alternate brackets but I didn’t end up using those. The DIN bracket for the SKR Pico is just slightly wrong, it’s got one hole out of place but it’s functional as-is probably.

- I did have to switch the input voltage.

- Again, I’m also slipstreaming the screw-on bracket instead of using VHB tape. It does fit my Zero. I printed it with PET-GF on my Ender 3v2 on a G10 bed with Elmers purple gluestick to make it not warp. I used the 4.6mm hole version, and I guess the big thing not explained is that the M3x6mm screws (I ended up using M3x8mm screws because the NoDrop nuts sometimes don’t quite grab with the 6mm length) are used to screw down the four mounting holes, plus one of them goes into the threaded insert via the tap on the side of the PSU. The M3x10mm screws go in through the side. And you really want to mount the power supply to the bracket before you mount the bracket to the printer.

- Out of a spirit of paranoia, I decided to order the BOM-spec AC power inlet from DigiKey and the matching fuse instead of using the one that came in the box. Not a diss on Formbot, just my own fastidiousness and paranoia.

- Also out of a spirit of paranoia, after I’d hooked up the wires as per the diagram (The wires are in the IEC scheme) I checked with my multimeter to make sure that things were actually connected right with the continuity probe. And then I plugged things in with just the power supply connected so I could make sure it’s actually putting out 24v and the polarity is as I expect it to be. And then I plugged in just the SKR Pico to verify that the 5v out wires were actually putting out 5v and the polarity was as I expected.

- Either the stepper motor thermal compound on the SKR Pico isn’t very sticky or it’s some kind of removable putty? I dono, this doesn’t make me feel very good at all.

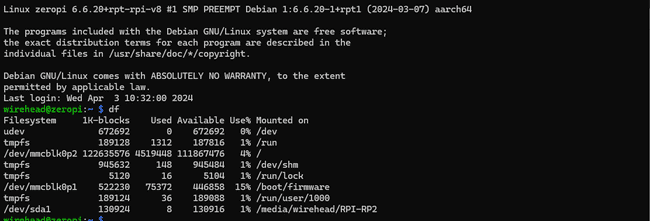

- I figure the best thing to do, at this point, is to get the current Klipper version and image installed now that I’ve got enough of it such that I can ssh in. So I set the jumpers for flashing mode, booted the pi… and now I have to actually provision the pi. Jumper clarification: The manual is vague about the purposes of the jumpers, but you only need to have the “USB Power” jumper closed if you aren’t powering the Pico via the 24v pin.

A brief word on my intended infrastructure

Understand that I’ve spent a lot of time doing various infrastructure work, both “in the cloud” but also on the real hardware. So… this is not going to be a normal Klipper setup process, because I’ve got opinions and I’m not afraid to whip out the chainsaw and cut things apart until it works the way I want it to work.

I’ve got an Intel NUC that’s set up with a mirrored array of real drives and that’s my home Linux box. If I’m talking to hardware with a Dockerized Linux-oriented build process like ESPHome, it’s a zillion times easier to plug the device into that than try to get USB connectivity routed through a hypervisor on my main computer.

Because Pi’s, up to the recent 5, are using SD or MicroSD cards for storage where they aren’t super trustworthy in terms of long-term longevity, I generally want to avoid having too much that’s running there that I can’t replace easily.

So, overall, I want things to be reproducable. Also, I don’t want my home DevOps infrastructure to get in the way of having fun.

Ansible is in a nice sweet-spot. Unlike everything that came before it (Chef, Puppet, et al) it doesn’t rely on an agent and control server, it just uses SSH to log in and do things, offering a vaguely reasonable but not especially pure intermediary between a stateless declaritive configuration language and the stateful operations required to actually apply changes to a running machine.

Docker is also in a pretty darn nice sweet-spot. There were docker-like things before Docker came out, such as lxc, but Docker provided a really amazing abstraction layer that, for better or worse, was real easy for folks to get started on.

Thus, my goal is to put the minimum amount of functionality, using Ansible to set up the box and then Docker to land the images, on the Pi, and then run as much of the higher-level tooling on my NUC.

Summary

This feels like a worthy accomplishment for “Why the heck is everybody ordering 100mm and 200mm MakerBeam XLs all of the sudden?” day