The eventual Dragon Burner upgrade

While purchasing things I keep thinking that maybe I should just get the much-hyped Nitehawk 36 and just go straight to DragonBurner.

But my LDO Sherpa was a pain in the butt that left me asking “Wait, isn’t LDO supposed to be the people who don’t send you weird semi-working shit with no manual?” So I decided that I’d wait a bit and see what happened.

This seems to be a good call. The NH36 seems to be a bit of a disaster in terms of early failures.

Not sure. I kinda wanted to be able to run 5v fans. The BTT EBB36 toolboard doesn’t make that easy; I’d have to run extra wires and stuff. There’s a Mellow toolboard that does, but the documentation’s lacking and I guess people had some reliability problems. Or I can wait till the NH36 situation is fixed?

ClockWork 2

The Formbot gear set is a little odd. I thought I was missing parts? It turns out that it’s just differently designed. Instead of the needle bearings on the inside of the BMG idler set, there’s two tiny little bearings that go on the shaft to hold the idler gear in place and the red main gear is an integrated assembly. This is the gears you get:

- “Tighten until the plastic bends and cracks. Back up 2 turns, discard parts, reprint and try again” is probably a little too jovial.

- Overall, this went fairly fast, probably because it’s mostly like the Zero’s MiniSB.

Tool Cartridge

- Missing part: You need a M2.5 × 8mm screw (I think - the mount is 5mm tall so 3mm into the DragonBurner sounds about right?) to mount the Dragon SF into the tool cartridge, but you don’t get one in the default kit package nor do you get one in the separate package that contains the Dragon.

- The measurement is nice (11mm) but a jig would still be better.

StealthBurner

- I hate it when it’s the “flair” features of the printer that get fiddly when building. In this case, the logo LED took a lot of effort to get it all snapped down right.

- This is the classic manual-flipping problem. I’ve gotta interweave between the Trident manual, the StealthBurner manual, the Tap manual, and then the EBB SB2209 CAN manual.

I’m skipping out on actually installing the StealthBurner and TAP until I’m ready to start the bringup process. When I was building the zero, I started with the power supply hooked up and verified that it was behaving and then added electronics a piece at a time and I’ll probably do that this time as well.

Wiring prep

- I thought that two of the brackets I’d placed were in a safe position, but it looks like they’ve got to go. Not sure how rigid the frame is at the moment.

- I’m doing the inverted electronics mod, so I had to spend a lot of time figuring out what direction some of the brackets were there to go.

- Some folks on the Voron discord were mentioning that the SSR’s tended to get a little hot in 110v countries for much the same reason why electric kettles suck. I’d done some random looking around for heatsink solutions and decided to try a cheap uxcell fin heatsink for SSR’s hoping that the height was such that it would fit inside of the inverted electronics bay with the SSR on top and that the ears did what I thought they were doing. And it fits! What’s not entirely evident from the description is that there’s a pair of ears that slide over a DIN Rail, so I looked forward to where the SSR was supposed to be and put it on that DIN rail and then installed it using the inverted electronics brackets and I’ll probably add a DIN clip to either side just to keep it from jiggling.

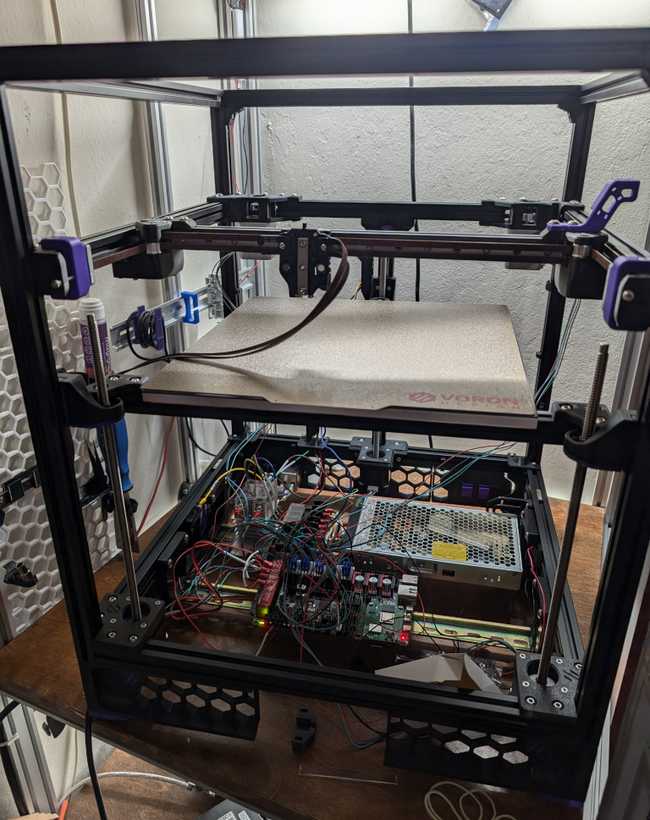

Electronics

This is where the Formbot config starts to differ:

- Instead of the wago 221-415 lever nuts for neutral, live, and protective earth, there’s the 3-to-6 board.

- Instead of the separate pi and controller, there’s a Manta M8P board.

- Similarly, there’s no 5v PSU.

- The X end-stop is wired through the toolhead board and so you mount the bumper to the stepper motor and then the switch gets screwed into the Tap, I think?

- The Y end-stop is wired up to where it usually is, I think?

- This has no cable chains other than the Z axis.

As far as assembly…

- For first power-up, I had Crafty Sorceress as the designated safety person in case I screwed up somehow and zapped myself.

- There are no M3×10 FHCS screws for the filtered inlet; I used M3×12 FHCS screws instead.

- The electronics bay arrangement was a bit dicey and I had to yank everything out and start over. The instructions say “Note: the DIN rails should be parallel to bed extrusions. or else, the wires may be not long enough.” and I’m not sure what that means. After the re-arrangement, everything seems to fit.

- The Fabreeko edge-to-edge heater bed’s thermistor cable wasn’t quite long enough. There’s an extension cable meant for the nevermore config the way they are doing it, which I’m not going to do, so I am using that instead.

- The diagram indicates that there’s one screw holding the side-skirts on, but there’s two, presumably because I’ve got the 300mm version.

- I am replacing the provided stock 60mm fans with CFM-6020V-237-280 fans.

- I printed the Y Endstop relocation mod to replace the endstop pod.

Provisioning with Ansible

For the most part, I’m able to re-play all of the same provisioning bits from the Zero, with a few of the steps forked such that the Zero files get put on the Zero’s pi and the Trident’s files get put on the Trident’s pi.

There was a good template for getting started with the Zero but there’s not one for the Trident. I ended up wasting a bunch of time because I’d screwed up some of the pin mappings. For a short period of time I thought I had a bad board.

Conclusion

It’s powered up and starting to work out…

What’s left, I think, before I can start trying to print a cube:

- Set up CAN interface.

- Provision the toolboard

- X and Y endstops

- Tighten the belt to spec

- Install the tap + stealthburner